The Benefits of Dry Ice Blasting for Bacteria, Fire Damage, and Grease Removal

The Benefits of Dry Ice Blasting for Bacteria, Fire Damage, and Grease Removal

Blog Article

Reveal the Factors Your Vehicle Will Take Advantage Of Automotive Dry Ice Blasting Strategies

Automotive completely dry ice blowing up techniques represent a significant advancement in lorry upkeep, providing a variety of benefits that extend past standard cleaning approaches. As the auto industry continues to welcome lasting practices, recognizing the full range of these advantages can essentially change just how you care for your automobile.

Eco Pleasant Cleaning

Among one of the most noteworthy benefits of solidified carbon dioxide blasting is its very little ecological effect. As the solidified carbon dioxide sublimates upon call with surfaces, it changes directly from strong to gas, leaving no additional waste. This particular not only preserves water however also removes the need for chemical ingredients that can be damaging to both the environment and human health and wellness.

Moreover, dry ice blasting is safe for numerous automobile parts, including delicate electric systems and complex engine parts. This technique boosts the general sanitation of cars while straightening with eco-conscious techniques, appealing to both vehicle professionals and ecologically mindful consumers (ice blasting). As the sector patterns in the direction of sustainability, solidified carbon dioxide blasting sticks out as a efficient and practical service in vehicle upkeep

Reliable Contaminant Removal

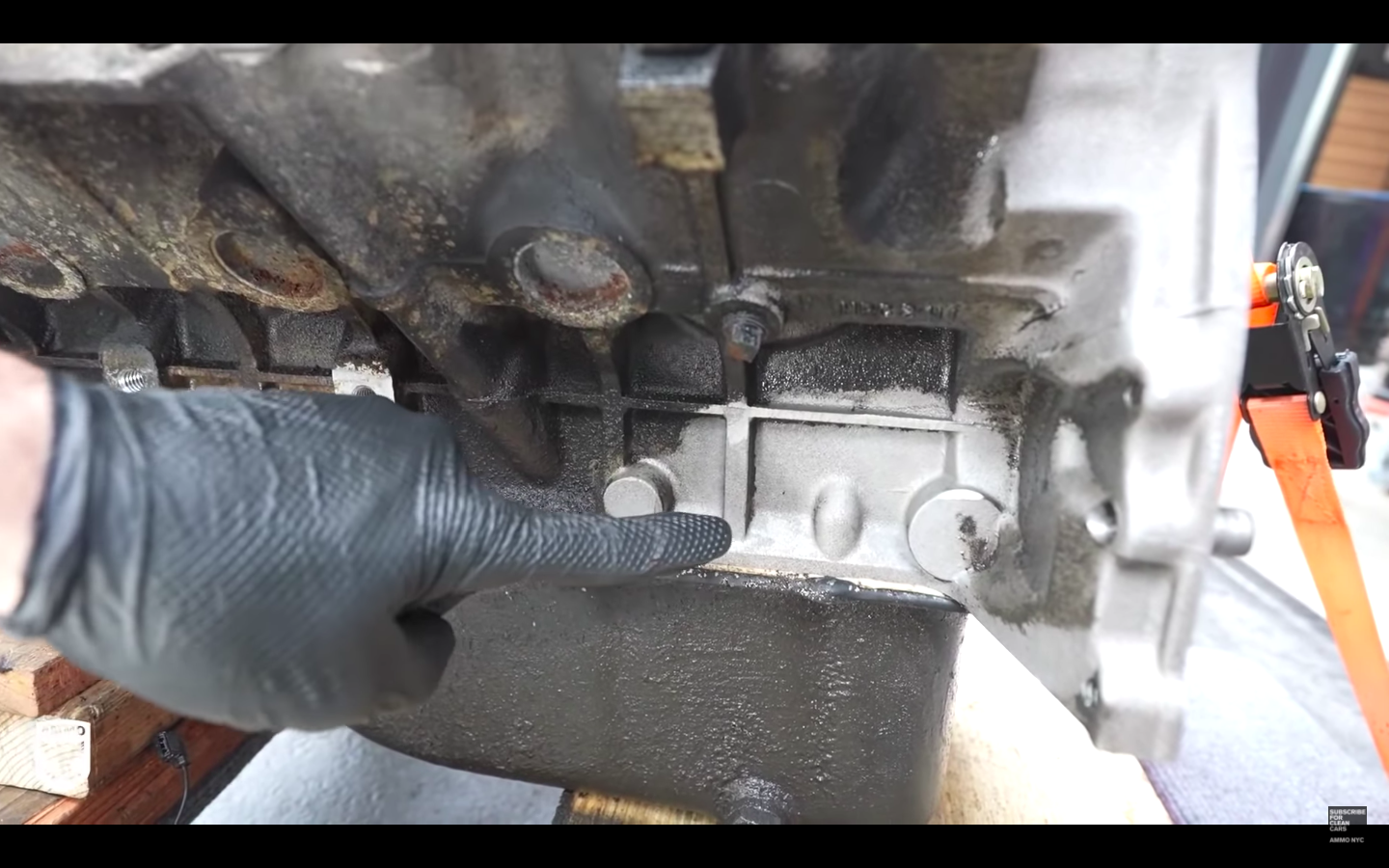

With a powerful mix of kinetic power and thermal shock, dry ice blasting excels in the efficient elimination of different impurities from automotive surfaces. This ingenious cleansing technique makes use of strong carbon dioxide pellets that, upon impact, sublimate and create a rapid temperature decrease. This process successfully displaces pollutants such as grease, carbon, oil, and dust deposits without the need for damaging chemicals.

The kinetic power produced throughout the blasting process moves the solidified carbon dioxide pellets at broadband, enabling them to penetrate the layers of grime and debris on engine elements, undercarriages, and various other hard-to-reach areas. As the pellets hit the surface, they expand and cause the impurities to break and fall away, resulting in a effective and extensive cleaning.

Additionally, solidified carbon dioxide blasting is specifically efficient for eliminating stubborn deposits that typical cleaning approaches have a hard time to get rid of. This includes baked-on materials that gather gradually, which can hinder efficiency and cause costly fixings - dry ice cleaning. By using this advanced strategy, vehicle proprietors can ensure their vehicles continue to be in optimal condition, improving both longevity and efficiency

Non-Damaging to Surface Areas

Dry Ice blasting not only masters pollutant elimination but additionally makes sure that surfaces remain intact throughout the cleaning procedure. This ingenious strategy uses strong carbon dioxide pellets that sublimate upon effect, developing a powerful yet mild cleaning approach. Unlike conventional abrasive cleansing methods, which can mar or scrape surface areas, solidified carbon dioxide blowing up operates at a reduced temperature and counts on kinetic energy to eliminate dust, grime, and various other pollutants without compromising the honesty of the underlying material.

The non-abrasive nature of solidified carbon dioxide blasting makes it especially helpful for delicate vehicle parts, such as electric systems, fragile paint surfaces, and complex engine components. As the solidified carbon dioxide pellets struck the surface area, they broaden and vaporize, leaving no deposit behind and minimizing the risk of damages. This particular not just maintains the visual allure of vehicles but also expands the life-span of crucial parts.

Time and Labor Efficiency

The effectiveness of time and labor is significantly boosted via the usage of dry ice blowing up in automobile cleansing processes. In comparison, dry ice blasting automates a lot of the cleaning procedure, allowing technicians to concentrate on various other necessary jobs.

Moreover, completely dry ice blasting gets rid of the need for disassembly of elements, as it can effectively clean complex locations without the danger dry ice blasting of destructive components. This not just shortens the general cleansing time but additionally minimizes labor prices related to reassembly and added labor hours. The solidified carbon dioxide pellets sublimate on contact, leaving no deposit behind, which even more improves the cleaning process.

In addition, the capacity to carry out dry ice blasting in situ implies that automobiles can stay operational during cleaning, decreasing downtime and boosting productivity. Therefore, vehicle specialists can serve a lot more customers within a given timeframe, eventually bring about improved workflow and effectiveness throughout the board. Embracing dry ice blasting is a calculated action for any kind of automotive service going for superior time and labor efficiency.

Economical Maintenance Option

A cost-effective maintenance remedy is vital for auto company wanting to maximize their success while supplying top quality results. Automotive solidified carbon dioxide blasting methods you can find out more supply an unique technique to lorry cleaning and maintenance, minimizing prices connected with conventional cleansing approaches. This innovative technique utilizes completely dry ice pellets to get rid of contaminants without the need for severe chemicals or extreme water, leading to substantial financial savings on both materials and disposal fees.

Furthermore, solidified carbon dioxide blowing up decreases labor time, permitting technicians to concentrate on additional services instead of comprehensive cleaning processes. This effectiveness equates right into quicker turn-around times for clients, improving general contentment and fostering repeat company. The environment-friendly nature of completely dry ice likewise positions company favorably in an environmentally aware market, bring in a bigger customers.

In addition, due to the fact that solidified carbon dioxide evaporates upon impact, there is no need for considerable drying out time, lowering downtime for automobiles and maximizing workshop performance. By taking on dry ice blasting, automobile provider can simplify their procedures, enhance solution offerings, and eventually enhance their profits. In recap, dry ice blasting is not simply an upkeep technique; it is a strategic financial investment that pays returns in efficiency and cost-effectiveness.

Verdict

In recap, automotive dry ice blowing up techniques offer a wide variety of advantages for lorry maintenance (dry ice blasting). This environmentally pleasant cleaning approach efficiently removes pollutants without causing damage to delicate surface areas. The effectiveness of the procedure not only preserves water yet likewise reduces labor time, making it an economical option for automobile proprietors. By taking on solidified carbon dioxide blasting, car maintenance becomes much more sustainable and reliable, eventually boosting the longevity and efficiency of automobiles.

Automotive completely dry ice navigate here blowing up strategies represent a substantial improvement in car upkeep, providing a range of advantages that expand beyond conventional cleansing approaches.In the world of automotive maintenance, ecologically friendly cleaning techniques have actually gotten substantial grip, with dry ice blasting emerging as a leading method.The effectiveness of time and labor is substantially boosted via the usage of completely dry ice blowing up in auto cleansing procedures. Automotive completely dry ice blasting methods provide a special technique to automobile cleansing and upkeep, lowering prices connected with standard cleaning methods.Additionally, because dry ice evaporates upon impact, there is no demand for considerable drying out time, decreasing downtime for cars and making best use of workshop performance.

Report this page